- Stock Brushes

- Custom Brushes

- Brushes By Shape

- Brushes By Type

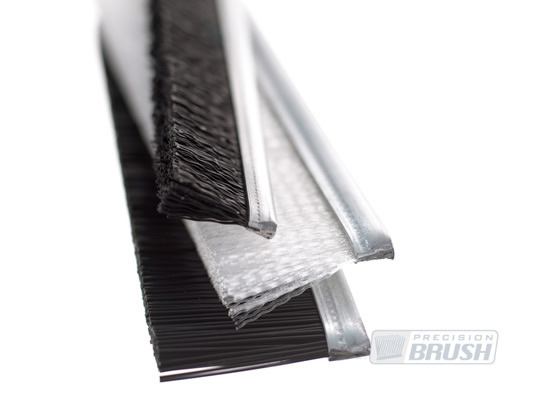

- Metal Channel Strip Brushes

- Flexible Strip Brushes

- Artist Brushes

- Staple Set Brushes

- Wire Drawn Brushes

- Conductive & Antistatic Brushes

- Anti Static Hand Held Brushes

- Anti Static Pencil Brushes

- Anti Static Strip Brushes

- Conductive Strip Brushes Brass

- Conductive Strip Brushes Thunderon

- Conductive Strip Brushes Conductive Nylon

- Conductive Hand Held Brushes

- Conductive Strip Brushes Stainless Steel

- Conductive Pencil Brushes

- Dissipative Brushes

- Dissipative Nylon Strip Brushes

- Dissipative Nylon Push Broom

- Insulative Strip Brushes

- Insulative Pencil Brushes

- Insulative Hand Held Brushes

- Titanium Brushes

- Twisted In Wire Brushes

- Epoxy Wound Brushes

- Step by Step Brush Design

- Common Uses

- Brush Holders

- Brush Info

- Design Sheets

- About Us

- Contact Us

Custom Brush Guards | Precision Brush

Since 1951, Precision Brush Company has been manufacturing strip brushes for use as brush guards in all kinds of applications. The brush guards are typically used on machinery, but they can also be used to effectively seal or wipe products.

Stock options are available, or you may design your own strip brush for use as a guard.

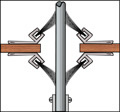

On machinery, the brush guards can be used to hide moving parts or to guard areas that are unsightly or possibly dangerous if left unprotected. Brush guards have been widely used in printing machinery, agricultural machinery, glass processing machinery, metal working machinery and packaging machinery.

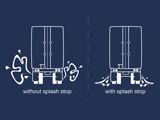

Brush guards have also been used to wipe products, like food from a conveyor, parts from a washer or machined chips. Brush guards can be used to clean parts or to keep hands a safe distance away from industrial chemicals. They can also be used to suppress harmful spray from paint booths or degreasing machinery. Brush guards can even be designed to enable hands to pass though a guarded area in order to adjust or clean machinery during scheduled maintenance. If there is not enough room to pass hands though, we can also design brush guards that can be removed quickly, such as road spray suppressants for trucks.

Precision Brush is the leading designer and manufacturer of strip brushes, and we ship our custom brush guards to many countries across the globe. Precision Brush is world-renowned for our extremely high standards of quality, fast delivery and efficient brush guard design.

Brushes can be used to shield machine tool or woodworking chips, vapors and fumes, paint booth overspray and even sound. Precision Brush seals can serve as light seals for dark rooms or be used to seal gaps on conveyors belts and lead screws. They can seal areas where moving parts pass, such as a lever or an overhead conveyor. Precision Brush machine guards can also be designed to maintain dynamic pressure differential or enhance vacuum performance.

Brushes that are used as machine guards are durable and highly effective in keeping out dust, dirt or machined chips while still allowing a full range of motion for moving components. Brush filaments have much better memory than rubber or vinyl seals, which can break down quicker from abrasion and friction. Solids like rubber also can exert excess drag and/or wear on moving parts, while brushes allow for easy movement.

Our studies have shown that nylon brushes can last millions of cycles while increasing component life and reducing maintenance on equipment.