- Stock Brushes

- Custom Brushes

- Brushes By Shape

- Brushes By Type

- Metal Channel Strip Brushes

- Flexible Strip Brushes

- Artist Brushes

- Staple Set Brushes

- Wire Drawn Brushes

- Conductive & Antistatic Brushes

- Anti Static Hand Held Brushes

- Anti Static Pencil Brushes

- Anti Static Strip Brushes

- Conductive Strip Brushes Brass

- Conductive Strip Brushes Thunderon

- Conductive Strip Brushes Conductive Nylon

- Conductive Hand Held Brushes

- Conductive Strip Brushes Stainless Steel

- Conductive Pencil Brushes

- Dissipative Brushes

- Dissipative Nylon Strip Brushes

- Dissipative Nylon Push Broom

- Insulative Strip Brushes

- Insulative Pencil Brushes

- Insulative Hand Held Brushes

- Titanium Brushes

- Twisted In Wire Brushes

- Epoxy Wound Brushes

- Step by Step Brush Design

- Common Uses

- Brush Holders

- Brush Info

- Design Sheets

- About Us

- Contact Us

Wheel Brushes Manufactured in USA | Precision Brush

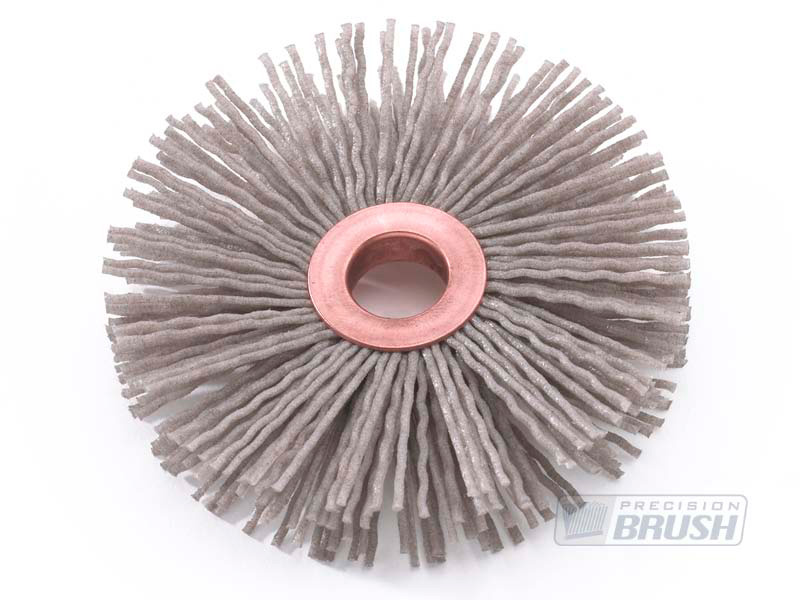

Copper Center Wheel Brushes

Copper Center Wheel brushes are manufactured using a copper tube, brush filament and a steel ring or washer. The filament is placed evenly around the outside of a copper tube. The washer is placed over the filament and, using a punch press, the tube is then formed into a “U” shape around the washer. This secures the filament, which is then trimmed to the proper outside diameter.

Brass is recommended in non-sparking environments. Urethane Encapsulated are also available for wire.

Safety Requirements:Operators must, at all times, observe common safety practices, such as wearing goggles, keeping machine guards in place, observing all speed restrictions, wearing appropriate protective clothing and comply with ANS-B165.1 - 1979 "Safety Requirements For The Design, Care And Use Of Power Driven Brushing Tools."

Copper Center Wheel brushes are available with Carbon Steel, Stainless Steel, Brass (for non- sparking applications) Nylon, Abrasive Nylon Horse Hair and Tampico filaments.

Ideal for the following applications:

- thread cleaning

- edge blending and finishing

- cleaning and polishing

- removing rust, scale and carbon

- cleaning boiler tubes

- aerospace and nuclear applications

- cleaning molds, dies and extruder barrels

Copper Center Wheels can be used individually or mounted side-by-side for a wider brush face. For wire stripping devices, two brushes can be mounted and programmed to rotate in opposite directions within close proximity. No matter what the application, high-speed operation is necessary for most effective use.