- Stock Brushes

- Custom Brushes

- Brushes By Shape

- Brushes By Type

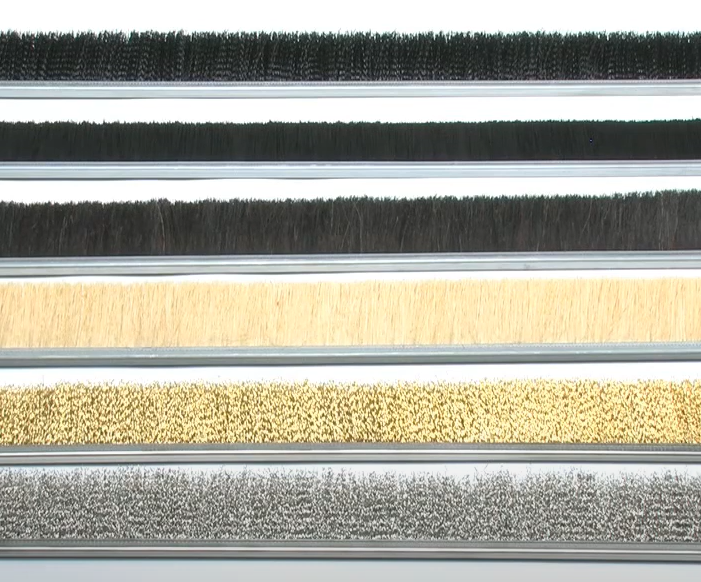

- Metal Channel Strip Brushes

- Flexible Strip Brushes

- Artist Brushes

- Staple Set Brushes

- Wire Drawn Brushes

- Conductive & Antistatic Brushes

- Anti Static Hand Held Brushes

- Anti Static Pencil Brushes

- Anti Static Strip Brushes

- Conductive Strip Brushes Brass

- Conductive Strip Brushes Thunderon

- Conductive Strip Brushes Conductive Nylon

- Conductive Hand Held Brushes

- Conductive Strip Brushes Stainless Steel

- Conductive Pencil Brushes

- Dissipative Brushes

- Dissipative Nylon Strip Brushes

- Dissipative Nylon Push Broom

- Insulative Strip Brushes

- Insulative Pencil Brushes

- Insulative Hand Held Brushes

- Titanium Brushes

- Twisted In Wire Brushes

- Epoxy Wound Brushes

- Step by Step Brush Design

- Common Uses

- Brush Holders

- Brush Info

- Design Sheets

- About Us

- Contact Us

Blog | Precision Brush - Custom Brush

Category: Custom Brush

Custom Brush Filaments for Optimal Performance

Enhance your equipment with Precision Brush's custom filaments. Over 400 filament options, expert guidance, and perfect for any environment.

NEED TO CUT YOUR BRUSH TO SIZE YOURSELF? HERE'S HOW.

Need to cut your brush to size yourself? Here’s how. Many times, a brush will need to be cut on site — after a customer receives the brush — to fit the intended application. For example, you might need to trim the brush down to fit a door; you could purchase a couple of long brushes and trim them to fit along the top and bottom. Brushes for dock leveler seals or the sides of a conveyor can be purchased long and trimmed down to size as well. To accomplish cutting your brush on site without damaging the brush, there are a couple of tips to keep in mind. Use a bolt cutter: Cut your brush with a bolt cutter, not a hacksaw or band saw. A bolt cutter will pinch the ends of the U-shaped metal channel together and keep the brush intact, whereas a saw will leave the end of the channel open and filaments can become loose and fall out. Deburr your edges: Use a file to smooth off any sharp edges after cutting. This step is especially necessary if the brush is being cut to fit in a brush holder. SIDE NOTE: It’s okay to use a saw to cut brush holders down to size; it’s just not recommended to use saws on the metal channels of the brushes themselves. Cutting brushes on site isn’t complicated; you just want to be sure to use a method that pinches the metal channel shut. Once you’ve cut your brush to the size you need, follow these tips if you are then placing it into a brush holder. Check your bristles: The brush should