- Stock Brushes

- Custom Brushes

- Brushes By Shape

- Brushes By Type

- Metal Channel Strip Brushes

- Flexible Strip Brushes

- Artist Brushes

- Staple Set Brushes

- Wire Drawn Brushes

- Conductive & Antistatic Brushes

- Anti Static Hand Held Brushes

- Anti Static Pencil Brushes

- Anti Static Strip Brushes

- Conductive Strip Brushes Brass

- Conductive Strip Brushes Thunderon

- Conductive Strip Brushes Conductive Nylon

- Conductive Hand Held Brushes

- Conductive Strip Brushes Stainless Steel

- Conductive Pencil Brushes

- Dissipative Brushes

- Dissipative Nylon Strip Brushes

- Dissipative Nylon Push Broom

- Insulative Strip Brushes

- Insulative Pencil Brushes

- Insulative Hand Held Brushes

- Titanium Brushes

- Twisted In Wire Brushes

- Epoxy Wound Brushes

- Step by Step Brush Design

- Common Uses

- Brush Holders

- Brush Info

- Design Sheets

- About Us

- Contact Us

Blog | Precision Brush - General

Category: General

Precision Brush Company: First Industrial Brush Manufacturer to Accept Stablecoin via Coinbase

Solon, Ohio – July 2025 – Precision Brush Company, a trailblazer in industrial brush manufacturing since 1951, has become the first industrial brush company in the world to accept stablecoin payments through Coinbase Payments, offering a seamless, secure, and modern checkout experience for its customers. Precision Brush is known for innovation and manufacturing custom-made metal channel for almost all industries. As a manufacturer of Metal Channel Strip Brushes, Coil Brush, Open Wound Coil Brushes, Disk Brushes and other formed shapes, they have been providing brushes made quickly on custom-made state of the art machinery since 1951. Just months ago, they pioneered crypto-friendly payments by accepting Bitcoin, Ethereum, and Litecoin. Now, the company is raising the bar again by integrating Coinbase Payments, enabling customers to pay in stablecoins, specifically USDC, directly and instantly. Unlike volatile cryptocurrencies like Bitcoin, stablecoins such as USDC maintain a 1:1 peg to the U.S. dollar—offering predictable value and minimizing transaction risk. Through Coinbase Payments, merchants can now accept USDC, providing customers with fast, cross-border payments and lower transaction fees compared to traditional wire or credit card payments. Benefits for Clients and the Company Near-instant settlement in a stable digital asset Low fees vs. bank wires or credit cards Global access without forex

Precision Brush - Company History

Precision Brush Company was founded in 1951 by Lloyd Benjamin in a small garage in Downtown Cleveland

Precision Brush - Colors of Brush Filament

Discover a wide range of filament colors for custom brushes at Precision Brush. From classic black to natural hues, find the perfect match for your

Precision Brush - Crimped or Level Brush Filament

Learn the differences between Level and Crimped brush fillings, and how they impact performance in applications like weather seals and cylinder

Precision Brush - Mounting a Cyclinder Brush

Discover how to mount cylinder brushes on shafts using secure methods like welding, clamps, and epoxy. Ensure a snug fit for optimal performance in any

All About Brush Channels

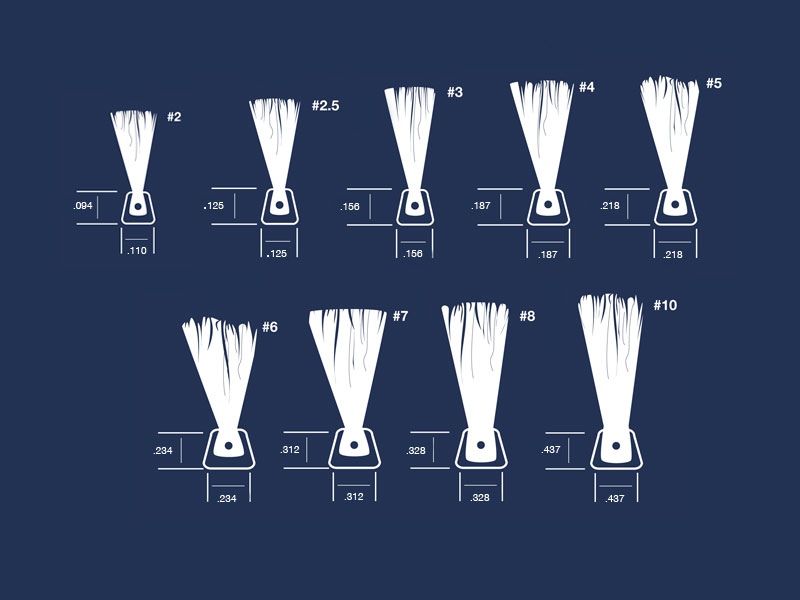

Understanding Brush Channel Construction Metal channel strip brushes all start out as flat steel on a roll. At Precision Brush, we offer several different brush-channel sizes: 2, 2.5, 3, 4, 5, 6, 7, 8, and 10. These numbered sizes each represent the total eighths of an inch in the metal channel before it is formed into a U shape. So, a one-inch-wide channel would be a size 8, indicating eight eights of an inch. A half-inch-wide channel would be a size 4 channel, and so on. Once a size is selected, the flat steel is then bent into a U shape, which creates the metal channel where the filaments will be held. The smaller the channel, the less filaments (size and quantity) it will hold. For example, if you want a heavy-duty brush with very stiff, thick filaments, you would need a larger channel. As channel size goes up, we can fit more filaments in the channel as well as use thicker filaments. For a short trim brush, smaller channels may be more appropriate. Longer trim brushes usually require a heavier, thicker filament, which necessitates a larger metal channel. Oval vs. Flat Channels Most of the time, channels have a flat bottom. This is the default style for channel construction. However, customers sometimes request an oval-shaped channel bottom. We offer this option in the number 5, 6, and 7 channel sizes. Sometimes, an oval channel may be selected when the final use of the brush will be a cup shape, such as in a round or oval-shaped vacuum brush. For most u

Cleveland Brush Manufacturers Host Filament Suppliers 2023

Cleveland Brush Manufacturers host filament suppliers, brush machine manufacturers and other brush manufacturers at the 63rd Annual Victor F. Miller Memorial Golf Tournament The Mill-Rose Company held the 63rd annual Victor F. Miller Memorial Golf Tournament at Shaker Heights Country Club in Cleveland, Ohio on Thursday, June 22, 2023. Brush manufacturers and suppliers from around the world gathered for the annual event. The golf event serves as the culmination of activities the week before where brush company representatives renew alliances, discuss business trends and opportunities for the brush manufacturing industry. Brushes manufactured by these companies are used in virtually every type of industry around the world. Applications include makeup/mascara brushes, hair brushes, floor sweeping and polishing brushes, gun cleaning brushes, car wash brushes, copier toner brushes, brooms, paint brushes, and special brushes used in the medical field. The weather was perfect for the golfing event. Skills of the golfers ranged from novice to near professional, however, a good time was enjoyed by all. Prizes were awarded to golfers for outstanding performance including: First Place, Low Gross – Dan Kirtz (Malish Corp) Second Place, Low Gross – Jim Benjamin (Precision Brush) Third Place, Low Gross – Tie Breaker between Chris Monahan (Brush Fibers) and RJ Lindstrom (Zephyr Manufacturing) going to Chris Monahan Closest to the Pin – Ian

What Happens When You Call Precision Brush?

When you search online for a metal channel strip brush, or to learn about the conveyor cleaning process, or when you’re looking for that unique custom brush, Precision Brush wants to be your first and only call. Who is the best person in your company to call us? What happens when you pick up the phone to speak with us on that initial call? Here at Precision Brush, we receive phone calls from a variety of people in various job roles. Sometimes we get a call from the purchasing agent, sometimes it’s the staff who are running the printing line at night who are directly using the brush, sometimes it’s the brush designer, and other times it might be the plant manager. We start the call by asking educated questions regarding the process of what the brush will be used for. This way we can understand how you plan to use the brush. You’re the expert on your machine or product, and we want our brush to fit your application or needs perfectly. We will ask about the pressure that you’re using, if the brush is being used in a heat application or process, the size of the holder the brush will need to fit into, etc. If the brush you want to order is a replacement for an old brush, then we will talk about what you need for brush replacements and about any issues you may have had in the past with previous brushes you’ve used. These questions help us be the brush experts we are. We will help you decide on the best metal channel for the brus

Industrial Brushes meet Artificial Intelligence

Precision Brush is the first brush manufacturer in the world to use Artificial Intelligence to write and produce a blog.

Check Out Our Video Library!

Explore the process of designing a custom brush, view design tools and find an answer to your questions in Precision Brushes video library.