- Stock Brushes

- Custom Brushes

- Brushes By Shape

- Brushes By Type

- Metal Channel Strip Brushes

- Flexible Strip Brushes

- Artist Brushes

- Staple Set Brushes

- Wire Drawn Brushes

- Conductive & Antistatic Brushes

- Anti Static Hand Held Brushes

- Anti Static Pencil Brushes

- Anti Static Strip Brushes

- Conductive Strip Brushes Brass

- Conductive Strip Brushes Thunderon

- Conductive Strip Brushes Conductive Nylon

- Conductive Hand Held Brushes

- Conductive Strip Brushes Stainless Steel

- Conductive Pencil Brushes

- Dissipative Brushes

- Dissipative Nylon Strip Brushes

- Dissipative Nylon Push Broom

- Insulative Strip Brushes

- Insulative Pencil Brushes

- Insulative Hand Held Brushes

- Titanium Brushes

- Twisted In Wire Brushes

- Epoxy Wound Brushes

- Step by Step Brush Design

- Common Uses

- Brush Holders

- Brush Info

- Design Sheets

- About Us

- Contact Us

Design a Staple Set Block Brush | Precision Brush

- Design a Straight Strip Brush

- Design a Cylinder Brush

- Design a Cylinder Brush Shaft

- Design a Cup Brush

- Design a Dampening Brush

- Design an Inside Coil Brush

- Design an Inside Curve Brush

- Design an Inside Disk Brush

- Design an Open Wound Coil Brush

- Design an Outside Curve Brush

- Design an Outside Disk Brush

- Design a Pencil Brush

- Design a Staple Set Block Brush

- Design a Staple Set Cylinder Brush

- Design a Twisted In-Wire Brush

- Design a Integral Core Design with Stepped Stub Shaft

- Integral Core Design with Stub Shaft

- Design a Set Screw Arbor Brush and Core Assembly

- Design a Solid Shaft Brush

Design Sheets

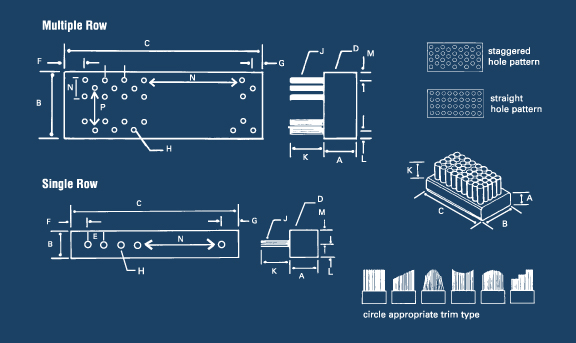

Staple Set Block Brush

Staple set block brushes are created using a block that has holes drilled into it in a particular pattern (determined by the requirements of the application). Filaments are stuffed into those holes in a U shape, and there is a staple that goes over the bottom of the folded filaments securing the filaments to the block.

A small quantity of these specialty brushes may be crafted by hand at our custom brush manufacturing facilities, and we can use our automated manufacturing equipment to produce large quantities, as well.

Wherever a unique filament pattern or core material is required, or when metal channel strip brush can’t be used, a staple set block brush can be the perfect choice. Other specialty brush uses might include a need for filament on more than one side of the block for unique cleaning applications. You can even make a brush with a single tuft, a single row or multiple rows as you require for your brushing applications.

Staple set block brushes can be used to cover a large area unlike Straight metal channel strip brushes which generally cover a line of space. Staple set block brushes can be used to support or clean broader product areas for brushing, holding or to slide parts easily without scratching.

As with metal channel brushes, there are countless industrial brush and customized brush applications. They are used in nearly every industry. Your imagination is the limit; our brushes can be customized in nearly any iteration.

Start your custom brush design now by completing the form below. If you’d like support from one of our experts, just give us a call.