- Stock Brushes

- Custom Brushes

- Brushes By Shape

- Brushes By Type

- Metal Channel Strip Brushes

- Flexible Strip Brushes

- Artist Brushes

- Staple Set Brushes

- Wire Drawn Brushes

- Conductive & Antistatic Brushes

- Anti Static Hand Held Brushes

- Anti Static Pencil Brushes

- Anti Static Strip Brushes

- Conductive Strip Brushes Brass

- Conductive Strip Brushes Thunderon

- Conductive Strip Brushes Conductive Nylon

- Conductive Hand Held Brushes

- Conductive Strip Brushes Stainless Steel

- Conductive Pencil Brushes

- Dissipative Brushes

- Dissipative Nylon Strip Brushes

- Dissipative Nylon Push Broom

- Insulative Strip Brushes

- Insulative Pencil Brushes

- Insulative Hand Held Brushes

- Titanium Brushes

- Twisted In Wire Brushes

- Epoxy Wound Brushes

- Step by Step Brush Design

- Common Uses

- Brush Holders

- Brush Info

- Design Sheets

- About Us

- Contact Us

Design a Twisted In-Wire Brush | Precision Brush

- Design a Straight Strip Brush

- Design a Cylinder Brush

- Design a Cylinder Brush Shaft

- Design a Cup Brush

- Design a Dampening Brush

- Design an Inside Coil Brush

- Design an Inside Curve Brush

- Design an Inside Disk Brush

- Design an Open Wound Coil Brush

- Design an Outside Curve Brush

- Design an Outside Disk Brush

- Design a Pencil Brush

- Design a Staple Set Block Brush

- Design a Staple Set Cylinder Brush

- Design a Twisted In-Wire Brush

- Design a Integral Core Design with Stepped Stub Shaft

- Integral Core Design with Stub Shaft

- Design a Set Screw Arbor Brush and Core Assembly

- Design a Solid Shaft Brush

Design Sheets

Twisted-In-Wire Brush

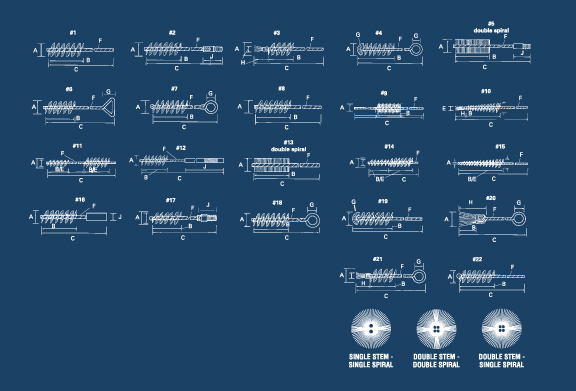

These custom brushes are made using wires — usually two, but sometimes four. Filament is laid between the wires and held securely on one end while a device on the other end twists the wires together. The filament spirals around between the wires to create a twisted-in-wire brush. Sometimes these specialty brushes are called stem brushes because they usually have a stem that is handheld or has a loop on it.

Twisted-in-wire brushes can be used for cleaning test tubes, holes, and in other general cleaning and industrial cleaning brush applications. They are often handheld, but the brushes may also be used in motorized applications if they need to spin in a drill or machine in order to deburr holes that have been machined, for example. They may be used on newly machined parts or well-used parts that require cleaning to remove coating or buildup.

These custom made brushes can be used to prepare a hole for being painted, powder coated, or anodized. Many times they are constructed with wire filament, but they may be made with other natural or synthetic filament materials as well.

Start your custom brush design now by completing the form below. If you’d like support from one of our experts, just give us a call.