- Stock Brushes

- Custom Brushes

- Brushes By Shape

- Brushes By Type

- Metal Channel Strip Brushes

- Flexible Strip Brushes

- Artist Brushes

- Staple Set Brushes

- Wire Drawn Brushes

- Conductive & Antistatic Brushes

- Anti Static Hand Held Brushes

- Anti Static Pencil Brushes

- Anti Static Strip Brushes

- Conductive Strip Brushes Brass

- Conductive Strip Brushes Thunderon

- Conductive Strip Brushes Conductive Nylon

- Conductive Hand Held Brushes

- Conductive Strip Brushes Stainless Steel

- Conductive Pencil Brushes

- Dissipative Brushes

- Dissipative Nylon Strip Brushes

- Dissipative Nylon Push Broom

- Insulative Strip Brushes

- Insulative Pencil Brushes

- Insulative Hand Held Brushes

- Titanium Brushes

- Twisted In Wire Brushes

- Epoxy Wound Brushes

- Step by Step Brush Design

- Common Uses

- Brush Holders

- Brush Info

- Design Sheets

- About Us

- Contact Us

Integral Core Design with Stub Shaft

- Design a Straight Strip Brush

- Design a Cylinder Brush

- Design a Cylinder Brush Shaft

- Design a Cup Brush

- Design a Dampening Brush

- Design an Inside Coil Brush

- Design an Inside Curve Brush

- Design an Inside Disk Brush

- Design an Open Wound Coil Brush

- Design an Outside Curve Brush

- Design an Outside Disk Brush

- Design a Pencil Brush

- Design a Staple Set Block Brush

- Design a Staple Set Cylinder Brush

- Design a Twisted In-Wire Brush

- Design a Integral Core Design with Stepped Stub Shaft

- Integral Core Design with Stub Shaft

- Design a Set Screw Arbor Brush and Core Assembly

- Design a Solid Shaft Brush

Design Sheets

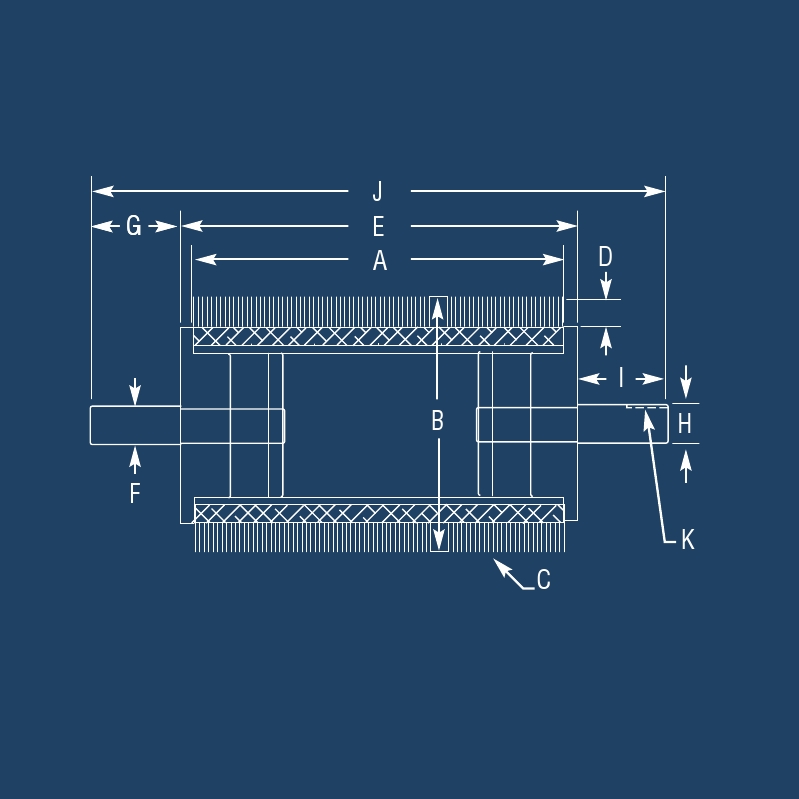

Epoxy Wound Cylinder Brush with Integral Core Design and Stub Shaft

Start Designing Now:

Cylinder Brush with Integral Core

Instead of a metal channel strip brush that is wound around a shaft, the cylinder brush with integral core is an epoxy wound brush, also known as a string wound brush — one that has filaments attached using strings covered in epoxy glue.

A series of strings pass through the epoxy glue, then those strings are wrapped around a shaft one on top of the other. One string winds around the shaft, then the next string winds around that string, and so on in a process that carries this winding out simultaneously. Filaments are placed between the strings and secured in place by the epoxy.

The epoxy wound brush is then cured overnight and the filaments are bonded in place. Each filament securely extends straight out of the brush and is not mechanically held around a center wire as are metal channel brushes.

The integral core refers to a brush that is ready to go, right out of the box. The shaft consists of stub ends that fit directly into your machine’s bearings. The stubs don’t go all the way through the brush, leaving the center hollow. For larger, heavier brushes, this core type is a better way to go so you don’t have a lot of weight in the center of the brush as it’s moving around. Cylinder brushes with an integral core may also be preferred for higher rpm applications, as they are more easily balanced to prevent wobbling.

These brushes are available in a wide variety of customer specifications, and cores can also be sent in for rewrapping.

Start your custom brush design now by completing the form below. If you’d like support from one of our experts, just give us a call.